Mining Electrical Safety

Online Training Certification Course

MSHA Part 46 & Part 48

From the highest rated and most trusted online training company - since 2008.

IMPORTANT * Before making a purchase be sure and read the GOVERNING REGULATIONS SECTION.

This online training certification course will highlight the regulations that cover mining electrical safety, the training requirements for working with and around electricity at mines, some of the most common mining electrical hazards, and ways to reduce or eliminate hazards.

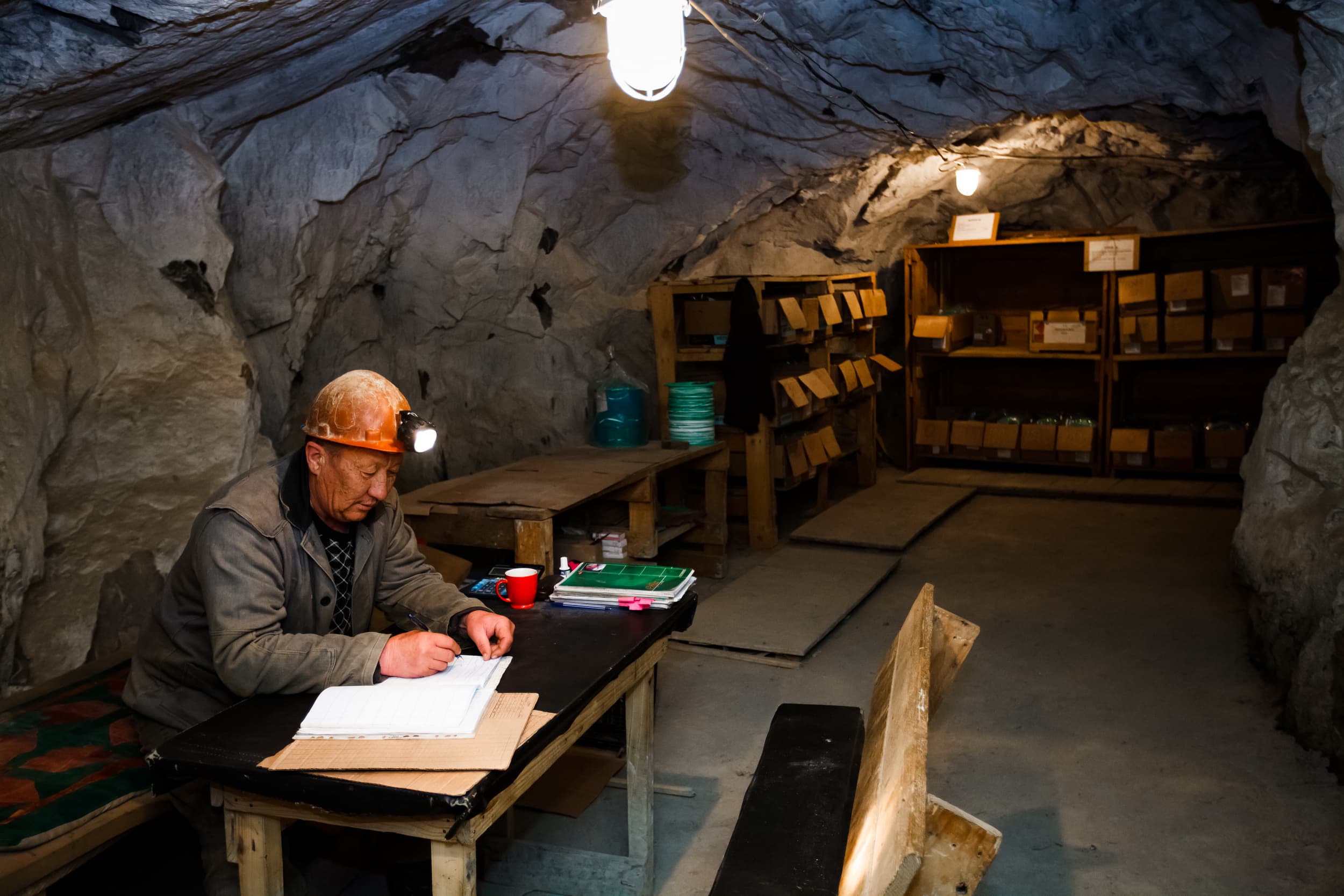

Mines present unique challenges for electrical safety. Working with or around electricity exposes miners and other onsite personnel to a range of hazards, including electric shock, arc flash, fire, and explosion. Comprehensive safety training helps prevent electrical injuries and fatalities.

This course is for:

This course is targeted at operators, supervisors, safety personnel, and all other individuals who work at mines.Every person at a mine site has a responsibility to ensure that health and safety standards are being observed at all times. This MSHA electrical training online course is intended for operators, supervisors, safety personnel, and all other individuals who work at mines.

Case Study: In July of 2011, a 39-year-old miner with 22 years of mining experience was electrocuted while welding two pipes together. He was working in the ceiling of the filter room of a preparation plant. The area in which the welding was being conducted was wet and dimly lit. The victim contacted an energized welding electrode, resulting in his death.

Key Takeaways: Never touch an energized electrode with bare skin. If possible, avoid wet working conditions. Even a person's perspiration can lower the body's resistance to electrical shock. Only work in a confined space if it is well-ventilated and illuminated.

Available languages: 100+ languages - translation provided by Google Translate (Select Language bottom of page)

Governing Regulations

MSHA divides their regulations into two parts: underground mining and surface mining. Electrical safety requirements for surface and underground mining are outlined in Title 30 of the Code of Federal Regulations (30 CFR) Parts 56, 57, 75, and 77. Because there is often an overlap in mining regulations, you may see regulations from other sections in 30 CFR referenced within this course.

On-site surface mine employees must receive this training. Training must also be available to contractors and visitors who want it.

TO BE MSHA COMPLIANT YOUR COMPANY MUST HAVE A MSHA APPROVED TRAINING PLAN AS OUTLINED BY 30 CFR §46.4. YOUR COMPANY CAN USE THIS OR ANY OF OUR COURSES AS PART OF THAT PLAN.

YOUR MINE SITE OPERATOR MUST PROVIDE YOU WITH A COMPLETED 5000-23 FORM UPON COMPLETION OF ALL REQUIRED ASPECTS OF TRAINING AS OUTLINED BY 30 CFR §46.8 WHICH MAY INCLUDE THIS SAFETY TRAINING AS WELL AS SITE SPECIFIC HAZARD TRAINING.

IT IS YOUR MINE SITE OPERATOR'S RESPONSIBILITY to Record and certify that each miner has received training required under this part on 5000-23 FORM, or on a form that contains the information listed in paragraph (b) of 30 CFR §46.9. The person signing the form is generally the mine operator, a person acting on behalf of the operator, or company safety official or instructor. Read more about how to complete the MSHA Form 5000-23 here.

For more information regarding what a MSHA training plan is and how our training can be implemented into your plan please reference 30 CFR §46.4.

If you are a mine owner or independent contractor and unsure how to write a training plan our “Making a Part 46 Training Plan” Instructional Course is available as a step-by-step guide. Part 46 Surface Mining Training Plan course.

What You'll Learn

- Introduction to Electrical Safety in Mining

- Key Terms

- MSHA Regulations

- NFPA Codes and Standards

- Local Regulations

- Applicability

- Mining Electrical Safety Overview

- Electrical Safety Statistics

- Electrical Safety Training

- Electrical Hazard Analysis

- SLAM Risks

- Electrical Safety Hazards

- Electric Shock

- Arc Flash

- Fire/Explosions

- Burns

- Batteries

- Power Lines

- Additional Hazards

- Lockout/Tagout

- Preparation

- Notification

- Isolation

- Dissipation

- Verification

- Maintenance and Service Operations

- Restoration

- Mining Electrical Safety Regulations and Requirements

- Grounding at Metal/Nonmetal Mines

- Electrical Requirements at Surface Mines

- Additional Electrical Requirements at Surface Mines

- Electrical Requirements at Underground Metal/Nonmetal Mines

- Underground Coal Mining Overview

- Underground Coal Mining-Permissible Electrical Equipment

- Underground Coal Mining-Electrical System Map

- Underground Coal Mining-Short Circuit Protection

- Underground Coal Mining-Lightning Arresters

- Underground Coal Mining-Grounding

- Underground Coal Mining-Repairing High-Voltage Lines

- Underground Coal Mining-Disconnect and Cut-off Switches

- Mining Electrical Safety Best Practices

- Personal Protective Equipment (PPE)

- PPE Requirements-Upper Body

- PPE Requirements-Torso and Lower Body

- Choosing PPE

- Additional PPE Requirements

- Portable Battery and Equipment Inspection

- Site Inspection and Maintenance

- Summary

- Additional Resources

- Exam

It will take a MINIMUM of 2 hours to complete this online course. The student may log on and off as needed. A bookmark will be set so when they log back in they will return to where they left off.

We have no restrictions on how long a person takes to complete a course. Likewise, if you are purchasing for others, we have no time limit on assigning courses, so you can purchase a larger quantity than you currently need and take advantage of volume discounts.

Miners must receive a minimum of 8 hours of annual refresher training. It must address health and safety subjects that are relevant to mining operations, as well as instructions on changes at the mine that could impact the miner's health or safety. Online training makes it easy to track and monitor annual refresher training, ensuring miners are following MSHA Part 46 regulations.

The refresher training must include instruction on changes at the mine that could adversely affect the miner's health or safety.

Refresher training must also address other health and safety subjects that are relevant to mining operations at the mine. Recommended subjects include, but are not limited to: applicable health and safety requirements, including mandatory health and safety standards; information about the physical and health hazards of chemicals in the miner's work area, the protective measures a miner can take against these hazards, and the contents of the mine's HAZCOM program; transportation controls and communication systems; escape and emergency evacuation plans, firewarning and firefighting; ground conditions and control; traffic patterns and control; working in areas of highwalls; water hazards, pits, and spoil banks; illumination and night work; first aid; electrical hazards; prevention of accidents; health; explosives; and respiratory devices. Training is also recommended on the hazards associated with the equipment that has accounted for the most fatalities and serious injuries at the mines covered by this rule, including: mobile equipment (haulage and service trucks, front-end loaders and tractors); conveyor systems; cranes; crushers; excavators; and dredges. Other recommended subjects include: maintenance and repair (use of hand tools and welding equipment); material handling; fall prevention and protection; and working around moving objects (machine guarding).

Miners must receive a minimum of 8 hours of annual refresher training. It must address health and safety subjects that are relevant to mining operations, as well as instructions on changes at the mine that could impact the miner's health or safety. Online training makes it easy to track and monitor annual refresher training, ensuring miners are following MSHA Part 46 regulations.

The refresher training must include instruction on changes at the mine that could adversely affect the miner's health or safety.

- Each miner shall receive a minimum of 8 hours of annual refresher training as prescribed in this section.

- The annual refresher training program for all miners shall include the following courses of instruction:

- Mandatory health and safety standards. The course shall include mandatory health and safety standard requirements which are related to the miner's tasks.

- Transportation controls and communication systems. The course shall include instruction on the procedures for riding on and in mine conveyances; the controls in effect for the transportation of miners and materials; and the use of the mine communication systems, warning signals, and directional signs.

- Barricading. The course shall include a review of the methods of barricading and locations of barricading materials, where applicable.

- Roof or ground control, ventilation, emergency evacuation and firefighting plans. The course shall include a review of roof or ground control plans in effect at the mine and the procedures for maintaining and controlling ventilation. In addition, for underground coal mines, except for miners who receive this training under 30 CFR 75.1504, the course shall include a review of the emergency evacuation and firefighting program of instruction in effect at the mine.

- First aid. The course shall include a review of first aid methods acceptable to MSHA.

- Electrical hazards. The course shall include recognition and avoidance of electrical hazards.

- Prevention of accidents. The course shall include a review of accidents and causes of accidents, and instruction in accident prevention in the work environment.

- Self-rescue and respiratory devices. The course shall include instruction and demonstration in the use, care, and maintenance of self-rescue and respiratory devices used at the mine. In addition, except for miners who receive this training under 30 CFR 75.1504, the training for self-contained self-rescue (SCSR) devices shall include:

- Hands-on training in the complete donning of all types of self- contained self-rescue devices used at the mine, which includes assuming a donning position, opening the device, activating the device, inserting the mouthpiece, and putting on the nose clip; and

- Hands-on training in transferring between all applicable self- rescue devices.

- Explosives. The course shall include a review and instruction on the hazards related to explosives. The only exception to this course component is when there are no explosives used or stored on the mine property.

- Mine gases. The course shall include instruction in the detection and avoidance of hazards associated with mine gases.

- Health. The course shall include instruction on the purpose of taking dust, noise, and other health measurements and any health control plan in effect at the mine shall be explained. The health provisions of the Act and warning labels shall also be explained.

- Such other courses as may be required by the District Manager based on circumstances and conditions at the mine.

- Refresher training may include other health and safety subjects that are relevant to mining operations at the mine. Recommended subjects include, but are not limited to, information about the physical and health hazards of chemicals in the miner's work area, the protective measures a miner can take against these hazards, and the contents of the mine's HAZCOM program.

- Where annual refresher training is conducted periodically, such sessions shall not be less than 30 minutes of actual instruction time and the miners shall be notified that the session is part of annual refresher training.

Each student will receive 0.2 CEUs (or 2 CMEs) from Compliance Training Online® for completing this course.

Ildefonso D

Mining Electrical SafetyMuy buena

Jason I

Mining Electrical SafetyIt was very helpful in my line of work.

THE BEST ONLINE TRAINING EXPERIENCE POSSIBLE

Fast

Your time is valuable. We've designed our site to be as fast as possible.

Easy to use

You'll never get lost or confused with us.

Immediate Access

There's no waiting period. Begin the course as soon as you sign up.

Anywhere Anytime

Internet connection and a computer, tablet, or smartphone.

Up to date

We update our courses as soon as new regulations come out.