Shipyard Machinery and Piping Systems Safety

Online Training Certification Course

29 CFR Part 1915 Subpart J

From the highest rated and most trusted online training company since 2008.

Case Study: A worker was attempting to crawl feet-first out of a bin through a hydraulic gate when his body came into contact with the electronic eye of the machine. This activated the hydraulic gate, which lowered onto the worker's neck, killing him instantly.

According to the employer, the gate's hydraulic valve was in an open position at the time the incident occurred, despite being shut off earlier that day. After further investigation, it was discovered that the employer had no lockout tags-plus procedures in place.

Key Takeaway: OSHA regulations require proper safety procedures to prevent energization, startup, or release of hazardous energy. Even though the gate's hydraulic valve was shut off earlier that day, it was not properly locked out or tagged to prevent the machine from starting up unexpectedly. An effective lockout tags-plus program, with proper training, could have prevented this tragic accident.

Available languages: 100+ languages - translation provided by Google Translate (Select Language bottom of page)

Governing Regulations

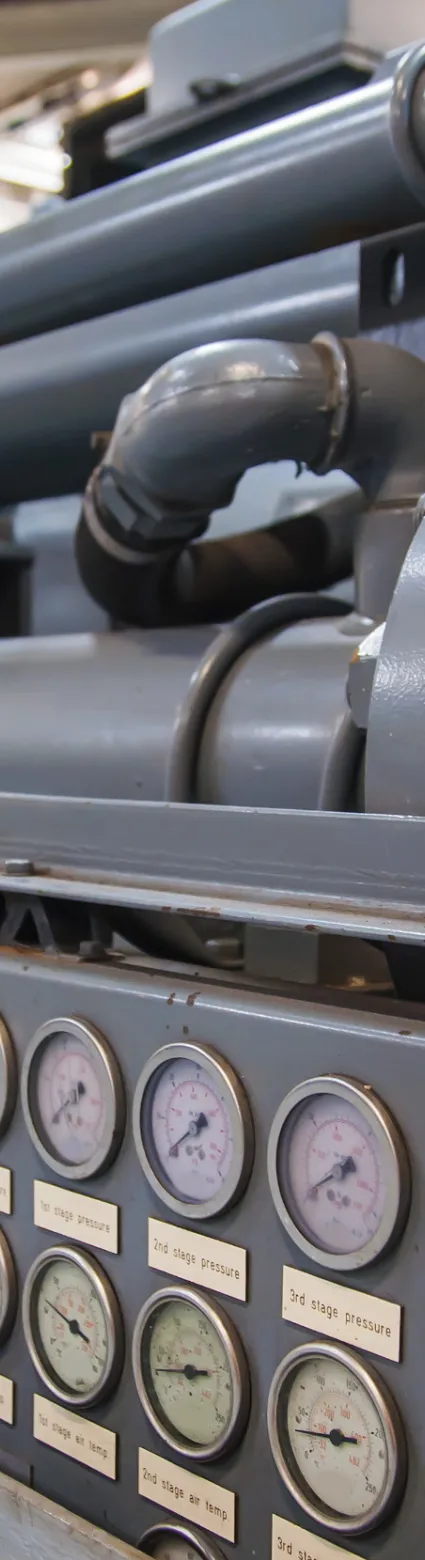

This course covers 29 CFR §1915 Subpart J "Ship's Machinery and Piping Systems," which contains regulations governing boilers, piping systems, propulsion machinery, and deck machinery for shipyard vessels. The course also touches on additional regulations such as 29 CFR §1917 "Marine Terminals," and 29 CFR §1918 "Safety and Health Regulations for Longshoring." These regulations detail safety precautions, procedures, and requirements for various deck machinery serviced in shipyards.

What You'll Learn

Introduction to Shipyard Machinery and Piping Systems Safety

- Key Terms

- Machinery and Piping System Injury and Fatality Statistics

Overview of Applicable Regulation

- Employer Responsibilities

- Employee Rights

- Safety Controls

Confined Spaces, Enclosed Spaces, and Dangerous Atmospheres

- Atmospheric Testing

- Atmospheric Monitoring

- Oxygen-Enriched vs. Oxygen-Deficient Atmospheres

- Flammable Atmospheres

- Toxic, Corrosive, Irritant, Corrosive, or Fumigated Atmospheres

- Rescue Teams

Lockout Tags-Plus for Ship Machinery and Piping Systems

- Lockout

- Tag Out and Tags-Plus

- Lockout Tags-Plus System Removal During Testing

- Removal of Lockout Tags-Plus System Procedures

- Startup Procedures

Machine Guarding

- Fundamentals of Machinery

- Other Types of Safeguarding

- Guards

- Machine Guarding Requirements

- Safety Devices

Marine Boilers

- Type of Marine Boilers

- Steam Safety Systems

- Water Safety Systems

- Fuel Safety Systems

- Safety Procedures for Servicing Marine Boilers

Piping Systems

- Piping Systems on Ships

- Safety Procedures for Servicing Piping Systems

Propulsion Machinery

- Types of Propulsion Systems

- Safety Procedures for Servicing Jacking Gears

- Safety Procedures for Servicing Propellors

Deck Machinery

- Types of Deck Machinery

- Cranes

- Crane Loading and Unloading

- Cargo Hatches

- Cargo Winches

- Anchors

- Mooring Winches

- Anchor Windlasses

- Gangways

Summary

Additional Resources

Exam

Our online courses will take at least 2 hours to complete, including the final exam, unless a different timeframe is specified in the course details. The learner may log on and off as needed. When they log back in, the course will return to where they left off.

Unless otherwise indicated in the course details, learners have 60 days from the date of enrollment to complete the course. During this time, participants can log out and back in to return to where they left off in the course. The only exception is the final exam, which must be completed in a single sitting.

Learners who do not complete the course within 60 days will have their enrollment disabled and not be eligible for a refund. Please review our Terms & Conditions for details.

Retraining is required when: (1) supervision and inspections indicate that the employee is not followingsafety-related work practices; (2) new technology, new types of equipment, or changes in proceduresnecessitate the use of safety-related work practices that are different from those the employee wouldnormally use; or (3) the employee must use safety procedures that are not normally used in his or herregular job duties. OSHA considers tasks that an employee performs less often than once a year as triggering the requirementfor retraining.